Changing Faces India FAQs

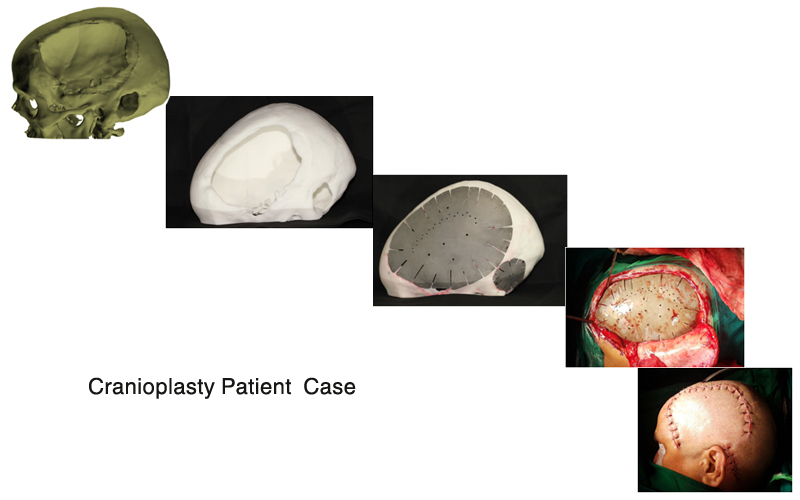

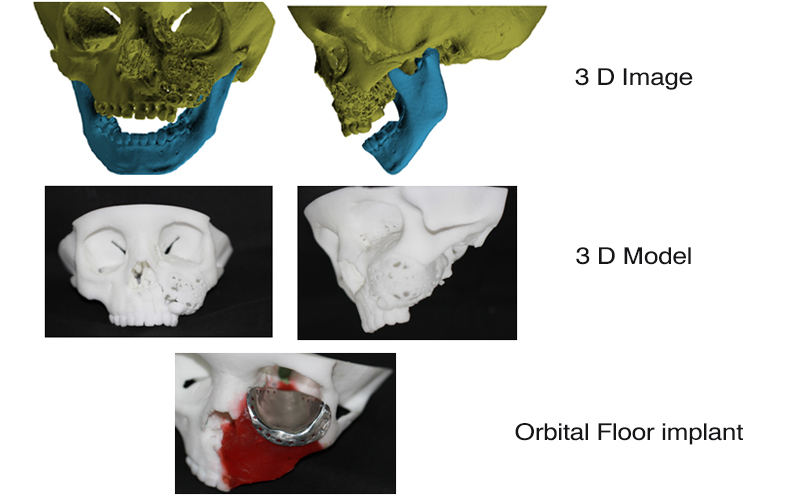

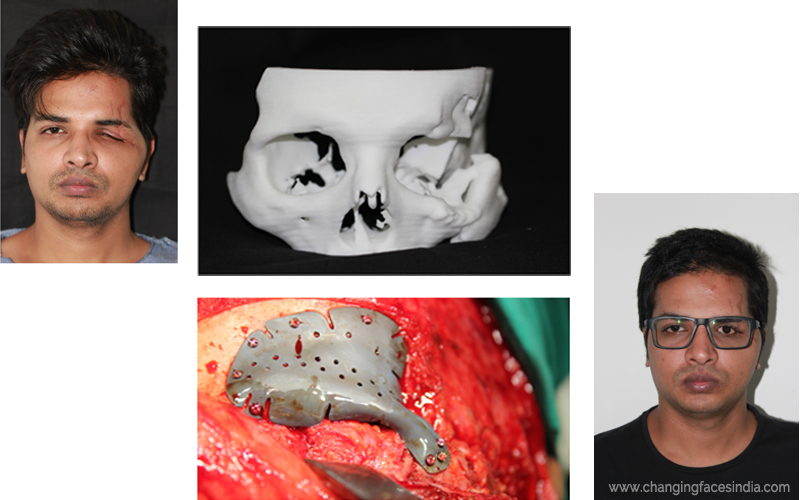

Recently a new therapeutic concept of patient-specific implant has been advanced based on computer-aided design/computer-aided manufacturing technology.

The Next-Generation Custom implants which combines accurate design with state-of-the-art technology.

Indeed we can manufacture large implants. A stronger implant a stronger implant eliminate the need for surgical correction in operation theater. Production of an implant without flanges is also much quicker, which allows us to give surgeons and patients a swift service (4 days turnaround).

It reduces the surgical time and also provides higher aesthetic out come.

Fast production turnaround, which facilitates enormously your planning, logistics and stock management, hence reducing costs and potential waste.

Perfect fit to the patient's defect with good cosmetic results.

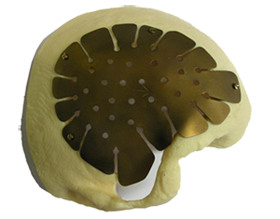

Our cranioplasty implants are made of pressed-sheet titanium

Cranioplasty Implants developed the Next-Generation cranioplasty implants which combine accurate design with state-of-the-art pressing technology. Indeed we can press very large implants. Stronger implants with a better fit of the implant to the defect and remove the need for the surgeon to contour and adapt in theater. Production of an implant without flanges is also much quicker, which allows us to give surgeons and patients a swift service.

Our temporal Implants provide a means for temporalis suspension to improve cosmetic outcomes.

Perfect fit to the patient's defect with good cosmetic results.

The Next-Generation design improves strength and removes the risk of local movement and flexing that may damage surrounding tissue and apply unnecessary force on screws.

Titanium is strong, biocompatible and has the lowest infection rate compared to ceramics, PMMA and autologous bone (ref)

Pressed-sheet titanium minimizes the amount of alloplastic material (e.g. less than 20% the material in titanium implants that mimic bone thickness) without any strength disadvantage.

Autoclavable – withstand repeated sterilization

Fast production turnaround, which facilitates enormously your planning, logistics and stock management, hence reducing costs and potential waste.

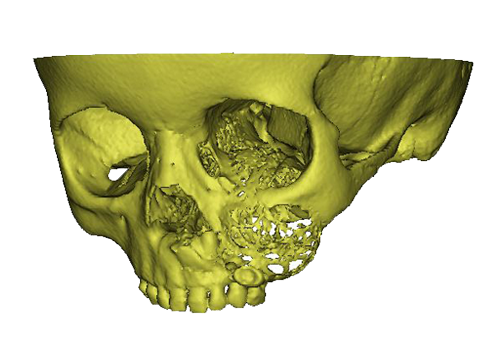

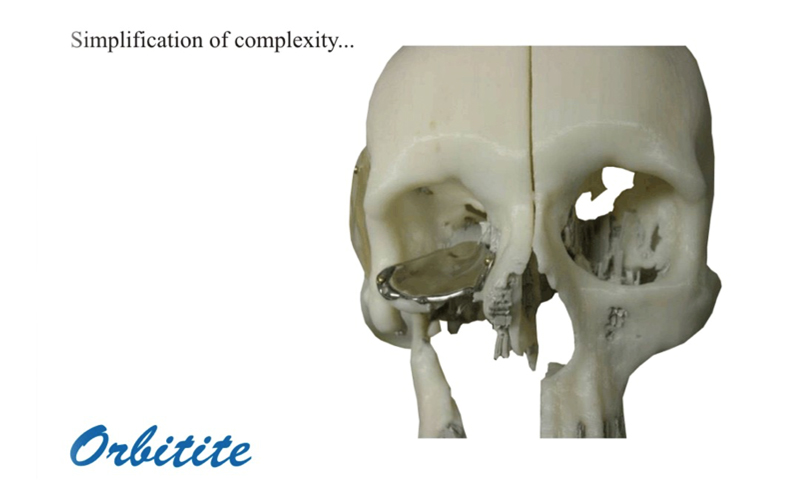

Orbital floor and wall repairs are notoriously difficult because their shape is critical to visual function. There is not a one-fits-all shape as every orbit is different. The extent of the defect also varies. Hence a functional repair needs to restore the original contour and therefore be customised. It is also important that the implant is physically able to be fitted and can be accurately positioned in the orbit, while avoiding critical structures.

Our implants are made of pressed-sheet titanium/milled peek . They fit over the orbital rim with screw attachment.

Fast production turnaround, which facilitates enormously your planning, logistics and stock management, hence reducing costs and potential waste.

The implant is stiffer than mesh so will hold shape much better during its positioning.

Reference points such as the alignment with the infraorbital foramen are indicated on the implant as much as possible to help with positioning.

Better fit of the implant to the defect, remove the need for the surgeon to contor and adapt in the operation theater thus and time saving

Reduces the surgical time

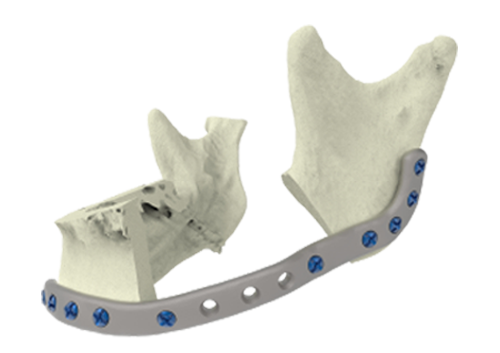

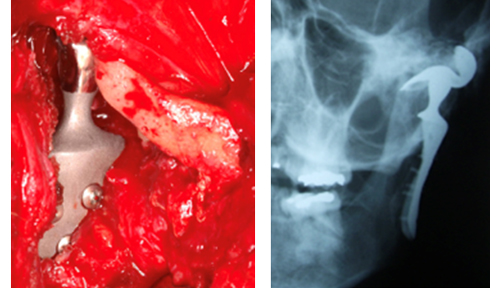

TMJ Implant Implacement system-Glenoid fossa and condylar implant.

Patient may have to undergone total TMJ Prosthetic reconstruction for different reasons such as trauma,degenerative diseases and cysts. TMJ reconstruction always includes both fossa and ramus condylar component.The method of TMJ reconstruction depends on the indication as well as on the extent of condylar resection.

The prosthesis comprises a condylar component for fastening to the mandible, the condylar component including a condylar head having a convex spherical articular surface; and a fossa component for fastening to the temporal bone, the fossa component having a concave spherical articular surface defining a socket being operable to engage the condylar head in an articulating manner wherein the concave spherical articular surface traverses through partially.

There is not a one-fits-all shape as every face is different. Our implants are customised and aim to create or restore symmetry.

It is also important that the implant is physically able to be fitted and can be accurately positioned where intended, while avoiding critical structures. We can tailor the implant design and fixation to fit in with the surgeon's chosen route of access.

Our implants are made of pressed-sheet titanium. They are fitted with screw attachment.

• Reference points such as the alignment with the other facial structures are indicated on the implant as much as possible to help with positioning

many cases, physical guides can also be provided.

• Customised titanium implants are much cheaper than those in porous polyethylene and PEEK

There is not a one-fits-all shape as every face is different. Our implants are customised and aim to create or restore symmetry.

It is also important that the implant is physically able to be fitted and can be accurately positioned where intended, while avoiding critical structures.

Our implants are made of pressed-sheet titanium. They are fitted with screw

• Reference points such as the alignment with the other facial structures are indicated on the implant as much as possible to help with positioning.

• In many cases, physical guides can also be provided.

• Customised titanium implants are much cheaper than those in porous polyethylene and PEEK

There is not a one-fits-all shape as every face is different. Our implants are customised and aim to create or restore symmetry.

It is also important that the implant is physically able to be fitted and can be accurately positioned where intended, while avoiding critical structures. We can tailor the implant design and fixation to fit in with the surgeon's chosen route of access.

Our implants are made of pressed-sheet titanium. They are fitted with screw attachment.

• Reference points such as the alignment with the other facial structures are indicated on the implant as much as possible to help with positioning

• In many cases, physical guides can also be provided.

• Customised titanium implants are much cheaper than those in porous polyethylene and PEEK

Customized eyelid implant weight for patient having Lagophthalmos

• Superior Esthetics

• Save intraoperatory time

Pre-Counctured Reconstruction Plate :- We provide pre-contoured reconstruction plates, especially suitable for mandibular body resection. These plates provide higher advantage over contouring reconstruction plates at the time surgery bye.

• Superior Esthetics

• Accurate post surgical occlusion

• Save intraoperatory time

• Provide better anchorage for bone graft at site of defect

Surgeons know that there are instances where the patient needs an implant to deal with their individual condition (for example following radiotherapy, patients with very scarred tissue). Our team will work hand-in-hand with the clinical team to create the appropriate solution for the patient.